Upgrade Your Workspace

Discover premium computer essentials and office supplies designed to boost your productivity and style.

Explore Gear

Babywear • Gifts • Toys & more

Discover premium computer essentials and office supplies designed to boost your productivity and style.

Explore Gear

Standard delivery charges apply.

Secure handling guaranteed.

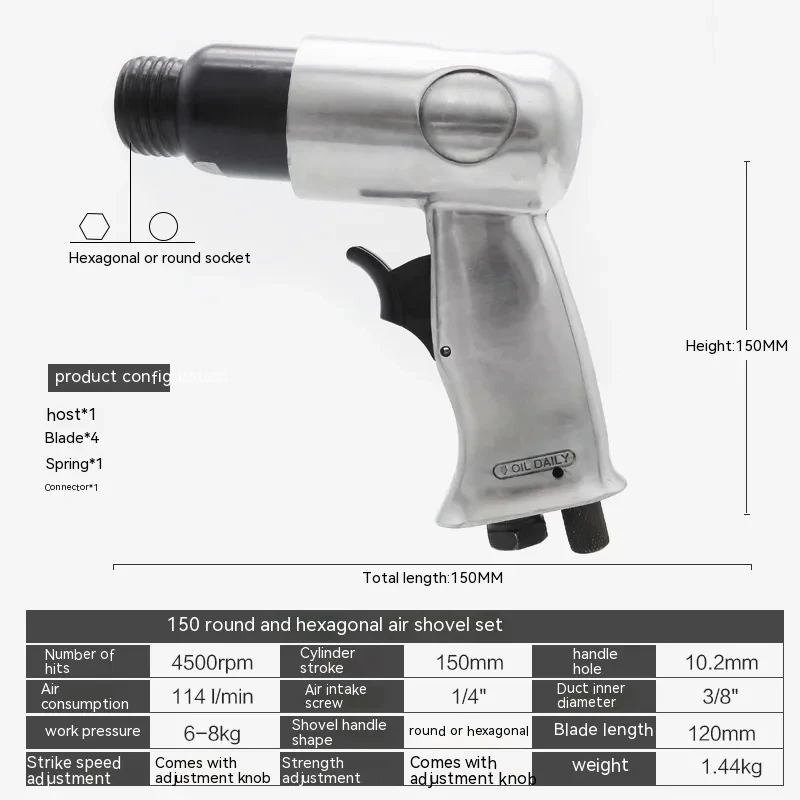

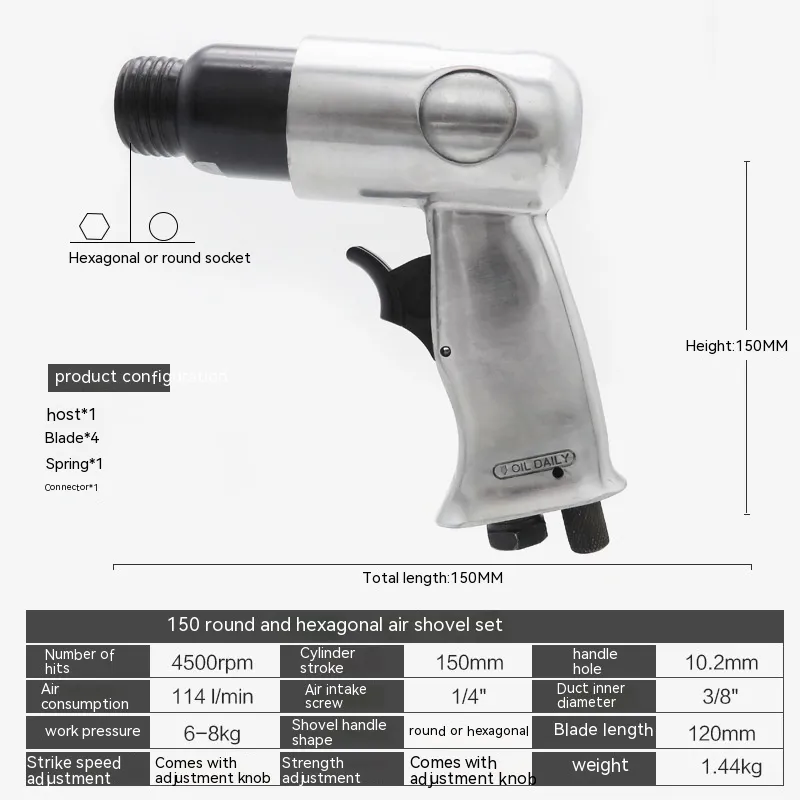

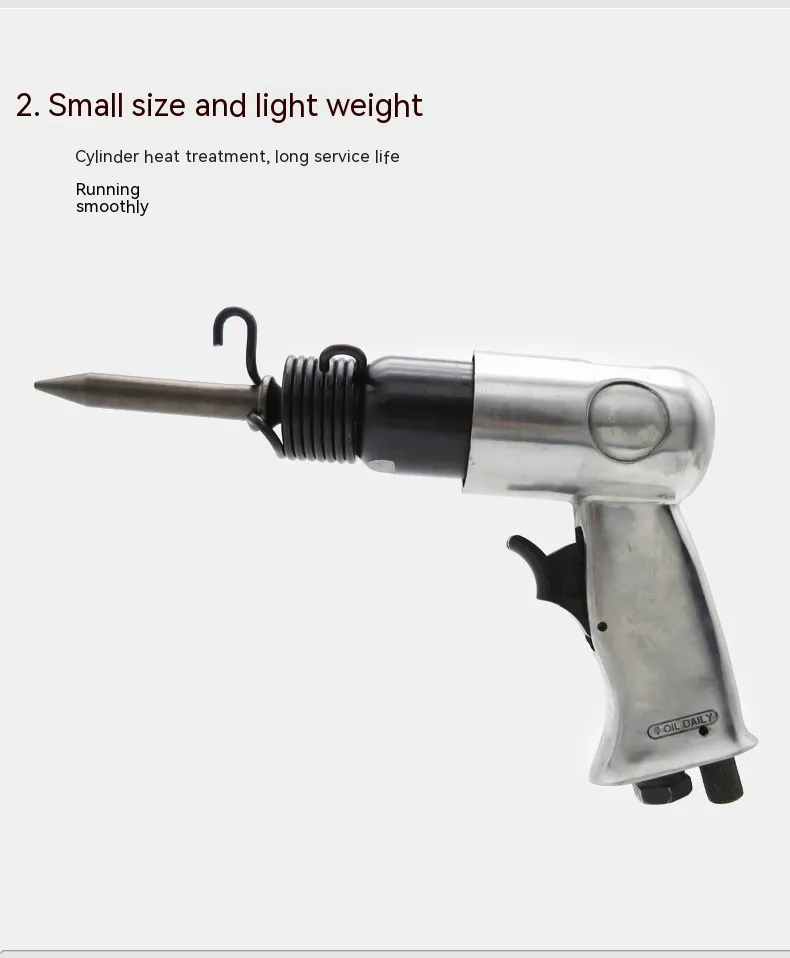

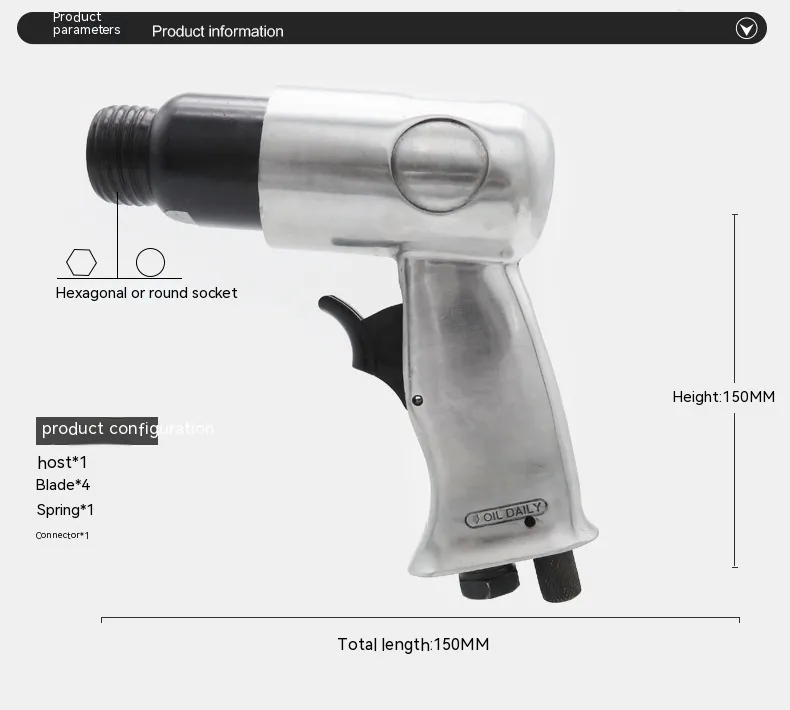

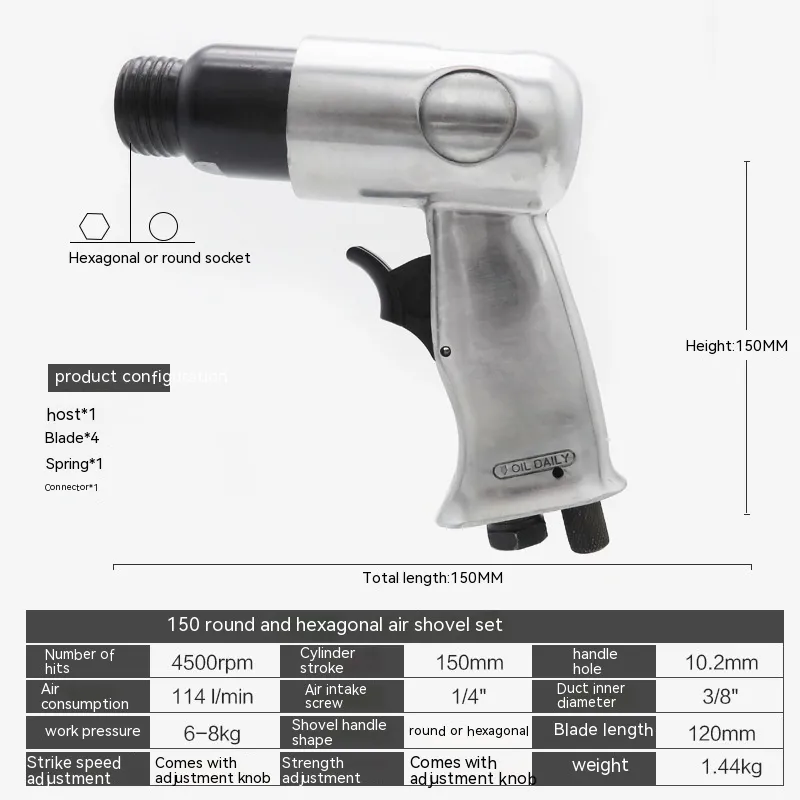

The Pneumatic Air Hammer Tool is an essential power instrument for any professional mechanic or DIY enthusiast looking to tackle heavy duty automotive and industrial tasks. This high performance tool uses compressed air to drive a piston, delivering rapid and powerful strikes that can easily break through rusted bolts, chip away at hard surfaces, or remove stubborn brake pads. Its robust construction and ergonomic design make it a reliable choice for long hours of work in workshops, tire shops, and construction sites. By integrating the Pneumatic Air Hammer Tool into your kit, you gain the ability to perform precision cutting and demolition work that would be nearly impossible with manual hand tools alone.

At the core of this tool is a sophisticated air delivery system that translates pneumatic energy into mechanical impact. The internal piston is designed for high frequency oscillation, allowing the user to apply consistent force with minimal physical exertion. This specific model is built with a heavy duty alloy steel barrel that resists wear even under constant vibration. The handle is shaped to fit comfortably in the palm, reducing the risk of hand fatigue during extensive rust removal projects. Whether you are a professional technician or a hobbyist working in your garage, the balance and weight distribution of this tool provide the stability needed for high precision chisel work.

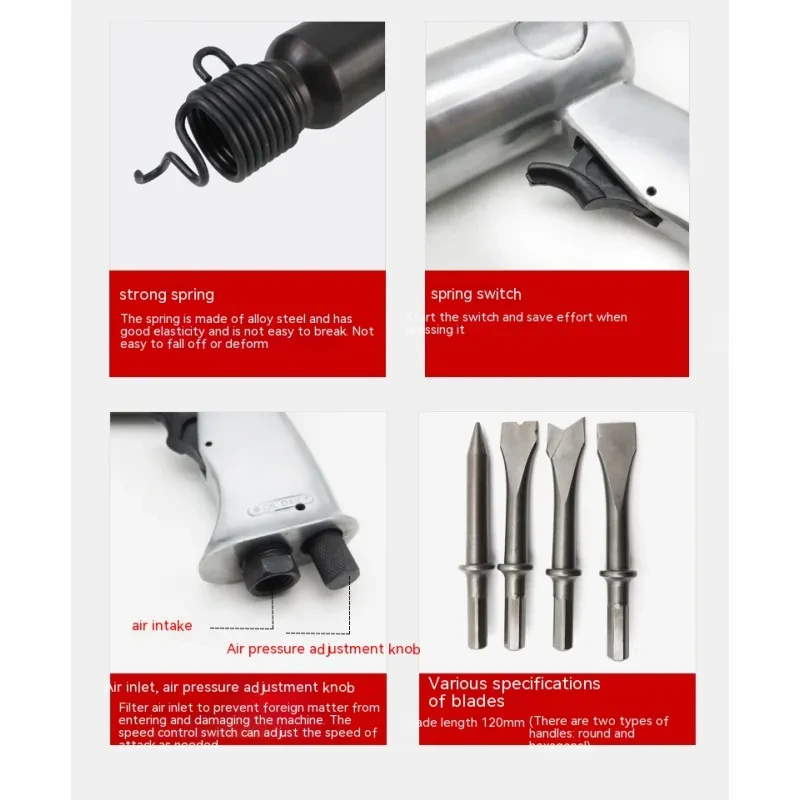

The longevity of a Pneumatic Air Hammer Tool depends heavily on the quality of its internal components and the exterior casing. This unit features a polished silver finish that protects the aluminum housing from corrosion and oil buildup common in automotive environments. The trigger mechanism is reinforced to handle thousands of cycles without losing responsiveness. Additionally, the quick change spring retainer ensures that your chisels stay locked in place during operation but can be swapped out quickly when moving from a cutting task to a surface cleaning job. This attention to detail in material science ensures that the tool remains functional even in the most demanding industrial settings.

| Specification Detail | Value / Measurement |

| Tool Type | Pneumatic Rock Drilling & Chisel Hammer |

| Handle Options | Hexagonal Suit / Round Handle Suit |

| Impact Rate | High Frequency Rapid Stroke |

| Housing Material | Reinforced Alloy Aluminum |

| Connection Type | Standard Air Inlet Nipple |

| Size Classification | 150mm Compact Industrial Class |

To ensure the best performance and safety while using your Pneumatic Air Hammer Tool, always start by lubricating the air inlet with a few drops of pneumatic tool oil. This keeps the internal piston moving smoothly and prevents rust inside the barrel. Connect the tool to a stable air source, typically set between 90 and 100 PSI for optimal power. Select the appropriate chisel head for your task—use the flat chisel for surface cleaning and the pointed chisel for breaking through welds or rusted metal. Hold the tool firmly with both hands, apply the tip to the work surface, and gently squeeze the trigger. The tool does the heavy lifting, so you only need to guide the direction and maintain steady pressure.

| Maintenance Task | Frequency |

| Air Inlet Oiling | Before Every Use |

| Retainer Spring Check | Weekly |

| Barrel Debris Cleaning | After Every Use |

| Air Pressure Calibration | Monthly |

| Internal Seal Inspection | Every 6 Months |

Packing list:

Air Shovel x 1pc

Product Image:

[BUYER_GUIDE]

When selecting a high quality Pneumatic Air Hammer Tool, the most critical factor is the choice between hexagonal and round handle shanks. A hexagonal handle suit is generally preferred by those who need the chisel to stay in a fixed orientation without rotating during use. This is vital for tasks like cutting straight lines in sheet metal or precisely removing a weld. On the other hand, round handle suits allow the chisel to rotate slightly under pressure, which can be beneficial for certain types of masonry or demolition work where the angle of impact needs to shift naturally. Understanding which shank type fits your specific mechanical needs is the first step in making a smart investment.

The second consideration is the impact frequency and stroke length. A shorter stroke length typically offers a higher frequency of hits, which is ideal for "finesse" jobs like removing rust from delicate body panels or cleaning up brake assemblies without damaging the surrounding metal. A longer stroke length delivers a heavier, more powerful blow suited for breaking through thick concrete or heavy industrial bolts. Our Pneumatic Air Hammer Tool is designed as a versatile "middle ground" option, providing enough power for heavy automotive repairs while remaining fast enough for detailed surface preparation. Buyers should always check the CFM (Cubic Feet per Minute) requirements of their air compressor to ensure it can keep up with the tool's air consumption during continuous operation.

Build quality of the retainer spring is another often overlooked detail. The spring is what keeps the chisel from flying out of the barrel during high speed operation. A weak or poorly made spring can be a significant safety hazard. Our recommended tool features a heavy duty coiled spring designed to withstand the violent vibrations of pneumatic impact. Furthermore, look for a tool that includes a standard air nipple in the box. Having the right connector ready to go means you can start your project immediately without making extra trips to the hardware store. Quality tools like this one also feature an exhaust port that directs air away from the work surface, preventing dust and rust particles from blowing back into your face.

Lastly, consider the weight and ergonomics. A tool that is too heavy will lead to shoulder and wrist fatigue within minutes. The 150mm size of this Pneumatic Air Hammer Tool is specifically chosen to provide a high power to weight ratio. It is compact enough to fit into tight wheel wells or under a vehicle chassis while still packing the punch needed for heavy duty rust removal. The matte finish on the grip ensures that even with oily or sweaty hands, you maintain a secure hold on the tool. By focusing on these technical aspects—shank type, air consumption, safety features, and ergonomic balance—you can choose a pneumatic tool that will serve you reliably for many years to decade. This guide is intended to help you look past the basic specs and understand the real world performance you can expect from a professional grade air hammer.

[FAQS]

Q: Does this air hammer come with the chisels shown in the picture?

A: Yes, the kit typically includes the main pneumatic gun along with a set of diverse chisel heads and the necessary retainer spring to get you started on various tasks right away.

Q: Can I use this tool with a small portable air compressor?

A: While it will function, a Pneumatic Air Hammer Tool performs best with a compressor that has a tank of at least 20 to 30 liters and can maintain a steady pressure of 90 PSI.

Q: What is the difference between the hexagonal and round handle suits?

A: The hexagonal suit prevents the chisel from rotating, which is better for precision cutting. The round suit allows some rotation, which is often preferred for general demolition or chipping.

Q: How often should I oil the tool to prevent internal damage?

A: You should add two to three drops of specialized pneumatic tool oil directly into the air inlet before every single use to keep the internal piston lubricated and prevent rust.

Q: Is this tool powerful enough to remove thick rust from a truck frame?

A: Absolutely. This air hammer is specifically designed for heavy duty rust removal and can easily scale off thick layers of corrosion from automotive frames and industrial equipment.

Q: Can I buy replacement springs if the original one wears out?

A: Yes, the retainer spring is a standard size and can be easily replaced. However, the high quality spring included with this set is built for long term durability.

Q: Is the trigger pressure sensitive for variable speed?

A: Yes, the trigger allows for some level of control. A light squeeze will result in slower, lighter taps, while a full squeeze delivers the maximum impact force for tough jobs.

Q: Can this tool be used for stone or masonry work?

A: While its primary design is for automotive metalwork, it is very effective for light masonry tasks such as removing old grout, chipping small stones, or cleaning mortar off bricks.

We deliver your orders quickly, safely, and securely. Most orders arrive within 7–21 working days. Local deliveries may arrive sooner.

Delivery times may vary based on location, order volume, and courier schedules. Some rural areas may take longer.

If your order hasn’t arrived within the estimated timeframe, please contact us: contact@giftdeal.com.au

A: Most orders are delivered within 7–21 working days Australia-wide. Local deliveries may arrive sooner.

A: Yes! Once your order is shipped, you will receive a tracking number via email.

A: Contact us within 48 hours with photos, and we’ll assist with a replacement or refund.

A: Yes, subject to our returns policy. Items must be unused and in original packaging.

A: Absolutely! We carefully source all products to ensure premium quality and customer satisfaction.

A: Email us at contact@giftdeal.com.au for any product, shipping, or order questions.

If you have other questions about sizing, compatibility, or features, please check the product description or reach out to our support team.

Buyer guide not available for this product.